- 현재 페이지경로

Smart Factory

The optimal process line is realized with the smart factory grafting the new digital technology to the manufacturing and production processes.

The production efficiency of the factory is improved maximally with the data analysis and forecasting.

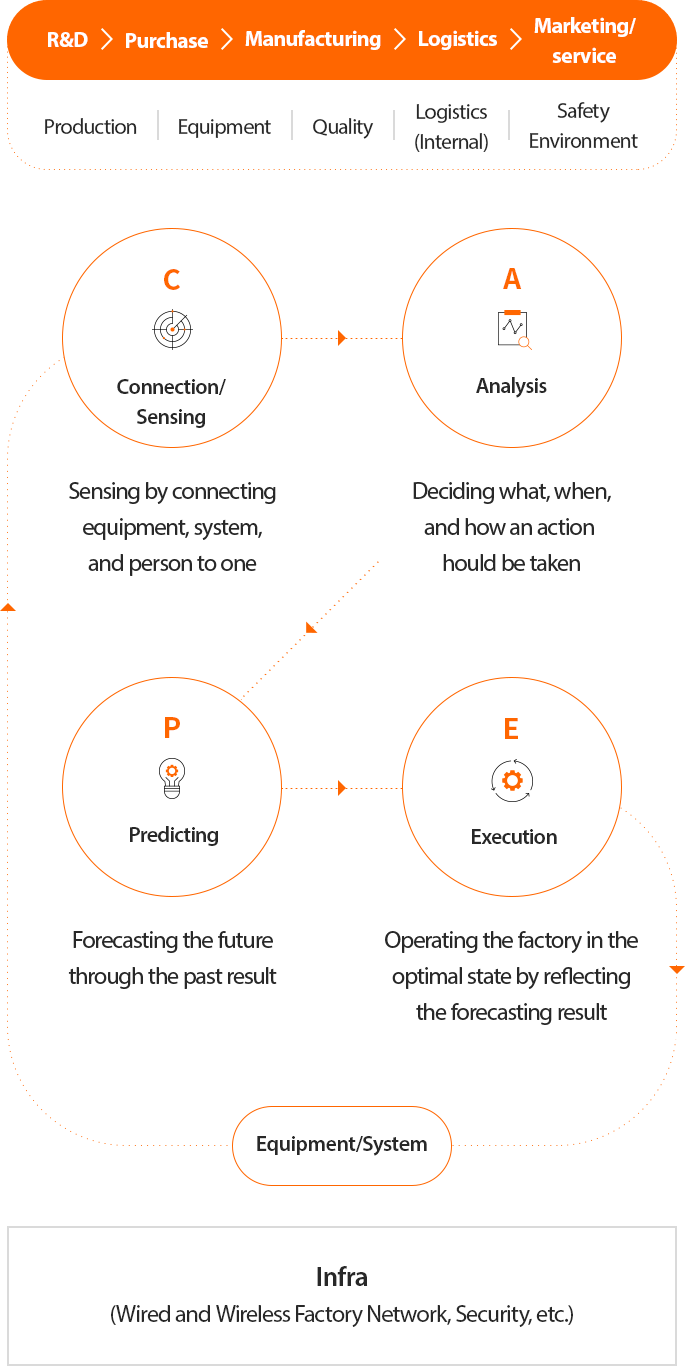

The smart factory (manufacturing DT) of Hanwha Systems performs the optimal production line through the collection, connection, analysis, and predicting needed for production by grafting the new digital technology to the manufacturing and production processes.

The process predicting and comparison are possible for any production line. Factory efficiency is upgraded maximally on the basis of the long-term experience of Hanwha Group in the factory automation and computerization project.

- Hanwha Smart Factory

- The factory enabling the optimized performance through the data connection, collection, analysis, and predicting by grafting the new digital technology to the manufacturing and production processes

-

- R&DProduction

- PurchaseEquipment

- ManufacturingQuality

- LogisticsLogistics (Internal)

- Marketing/serviceSafety Environment

-

- CConnection /SensingSensing by connecting equipment, system, and person to one

- AAnalysisDeciding what, when, and how an action should be taken

- PPredictingForecasting the future through the past result

- EExecutionOperating the factory in the optimal state by reflecting the forecasting result

- Infra (Wired and Wireless Factory Network, Security, etc.)

Major Service Areas

-

Consulting Service

Diagnosis and resolution are sought by finding the problem with the perfect manufacturing and production process analysis. Moreover, the information strategy needed for establishing the factory IT master plan is established with the PI consulting done.

-

Building Service

The task needed for building the smart factory is performed with the advanced ICT technology possessed by Hanwha Systems. The manufacturing application is developed and provided on the basis of the experience in doing various projects.

-

Maintenance/Operation Service

IT and OT (outsourcing) are performed for the efficiency of the smart factory with the more systematic and more efficient system operation advocated.

Expected Effects

- The standardization of the factory process and IT/OT is led with the contribution to the productivity improvement through process integration.

- Process prediction and preparation are always possible by preparing the data-based real-time decision-making system.

- Change to the innovative process constitution is possible by promoting the more systematic and steadier factory operation through the preparation of the mid- and long-term factory operation efficiency plan.

- The preemptive market response is possible to minimize the inventory and optimize the operation rate resulting in the contribution to the reduction of various expenses and costs.

- Productivity, quality, and customer satisfaction can be improved so that market competitiveness can be secured more.

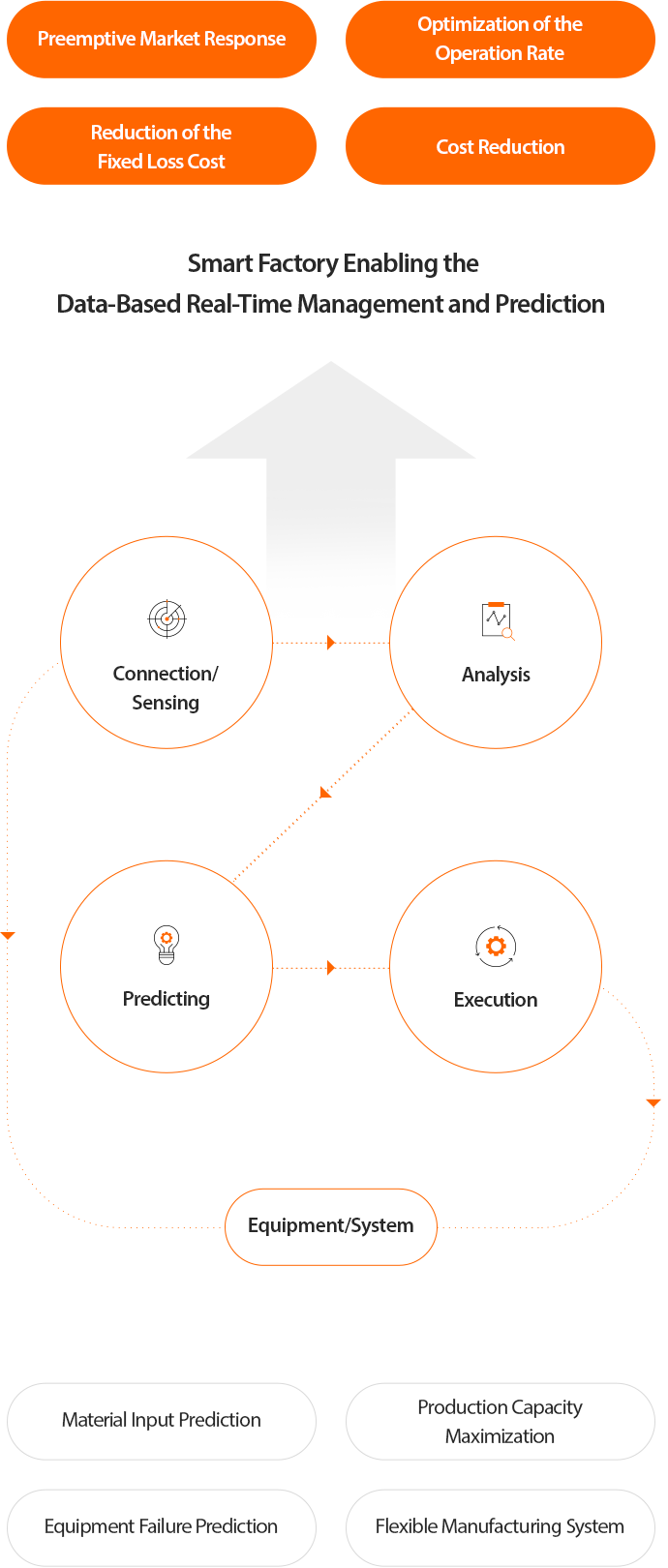

- Smart Factory Enabling the Data-Based Real-Time Management and Prediction

- Preemptive Market Response Optimization of the Operation Rate Reduction of the Fixed Loss Cost Cost Reduction

-

- Connection/Sensing

- Analysis

- Prediction

- Execution

- Material Input Prediction Production Capacity Maximization Equipment Failure Prediction Flexible Manufacturing System